Effect of flow stress on finite element predictions of metal flow lines in forging

페이지 정보

작성일posted onLink

본문

Effect

of flow stress on finite element predictions of metal flow lines in forging

In the previous article, it

was mentioned that the relatively small dead metal region due to flow stress

model employed may cause the difference, which gives us an idea with

expectation that a lower limit of flow stress model, i.e., initial yield stress

will improve the problem.

In this very short but important

article, the effect of flow stress on the FE predictions of metal flow lines is

discussed.

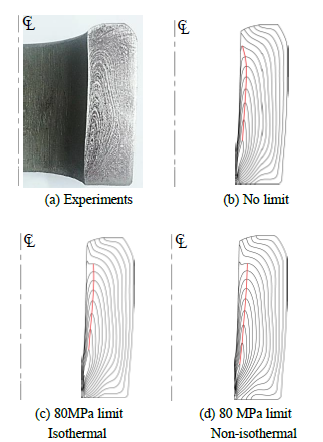

Figure 1 compares the metal

flow lines predicted by the power-law flow stress model without limit (see Figure

1(b)) and with lower limits of 80 MPa under isothermal (see Figure 1(c)) and

non-isothermal (see Figure 1(d)) conditions. It can be seen that the metal flow

lines after the piercing stage shown in Figures. 1(c) and 1(d) which were

predicted by the power-lar flow stress with the lower limit of 80 MPa are in

much better agreement with the experiments, compared to those obtained by the power-law

flow stress without any lower limit in Figure 1(b). It is noteworthy that a

detailed investigation shows that non-isothermal predictions in Figure 1(d) are

the closer to the experiments, compared to the isothermal predictions in Figure

1(c) in terms of slope of the metal flow lines especially on the bottom side.

comparison between the experiments and predictions under various conditions of them. It was revealed that a conventional flow stress model, called power-law flow stress model

cannot reflect the real state with higher accuracy especially near the dead metal zone. This causes the

smaller predicted dead metal zone which can have much influence on the metal flow lines especially in upsetting a long billet, i.e., a little smoothed metal flow lines. It was shown that this inaccuracy could not be neglected after the piercing stage. A realistic engineering solution of this problem is to use the conventional power-law flow stress model with lower limit of flow stress because most flow stresses are prepared based on the power law flow stress model at the elevated temperature.

Figure 1. Comparison of metal flow lines