Finite element analysis model of rotary forging for assembling wheel hub bearing assembly – Post 1

페이지 정보

작성일posted onLink

본문

Finite

element analysis model of rotary forging for assembling

wheel hub bearing assembly - Post 1

This

topic will be covered under a series of posts starting from this week.

In the past the wheel hub bearing assembly was assembled by incredible methods which were much dependent on the manual experience. Thus, the tolerance changed from situation to situation. It has passed quite long time since rotary forging approach was used to fabricate the wheel hub bearing assembly. The shaft clinching technology was developed to meet the requirement of customers on light weight and improved wheel bearing performance. The rotary forging approach needs quite higher assembly time compared to a kind of simple forging approach. However, rotary forging requires relatively small forming load with the result that precision assembly can be achieved. Of course, due to quite large assembly time of the rotary forging approach, a direct forging method has been studied but failed because of difficulty in controlling the preload within the required accuracy and frequent fracture of the hub bearing unit.

In the series of posts, an analysis model of the rotary forging for fabricating wheel hub bearing assembly is presented, based on the method of artificial planes of symmetry and the predictions are compared with experiments.

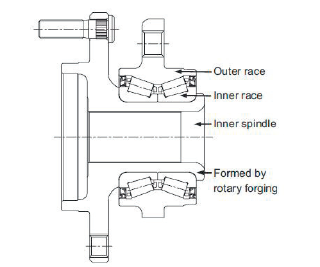

Figure

1 shows the schematic drawing of a wheel hub bearing assembly of which

manufacturing approach is studied in this paper. This assembly is fabricated by

assembly of a hub machined after forged and a hub bearing unit by a cold rotary

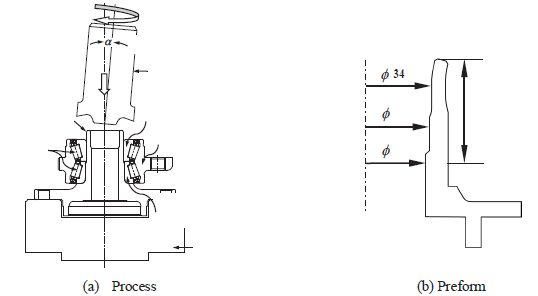

forging process. Figure 2 shows the mechanism of the rotary forging process for

assembling the hub and the hub bearing unit. During being assembled, the

bearing unit can be fractured if the excessive forming load is exerted. Also,

the preload endowed in the hub bearing during assembly process has a strong

influence on the performance of the assembly in its service because it can

affect the wear characteristics of the assembly. Thus, the forming load should

be properly controlled.

Figure 1. Schematic drawing of

wheel hub bearing assembly under investigation

Figure 2. Schematic drawings of process and preform to fabricate wheel hub bearing assembly

In addition, because the end of the hub is much elongated in the circumferential direction during the assembly process, it sometimes exposes to ductile fracture due to the cumulative damage. For this reason, the contact condition between the end region of hub and the inner race of hub bearing should be optimally controlled and thus the optimal initial shape of hub material and optimal process parameters should be utilized for the successful assembly procedure.

In the next week’s article, the details about the analysis model, meshing scheme and other relevant simulation parameters will be discussed. Stay tuned.

Do follow us on LinkedIn to

stay updated and know more interesting simulation examples from a wide variety

of metal forming processes.